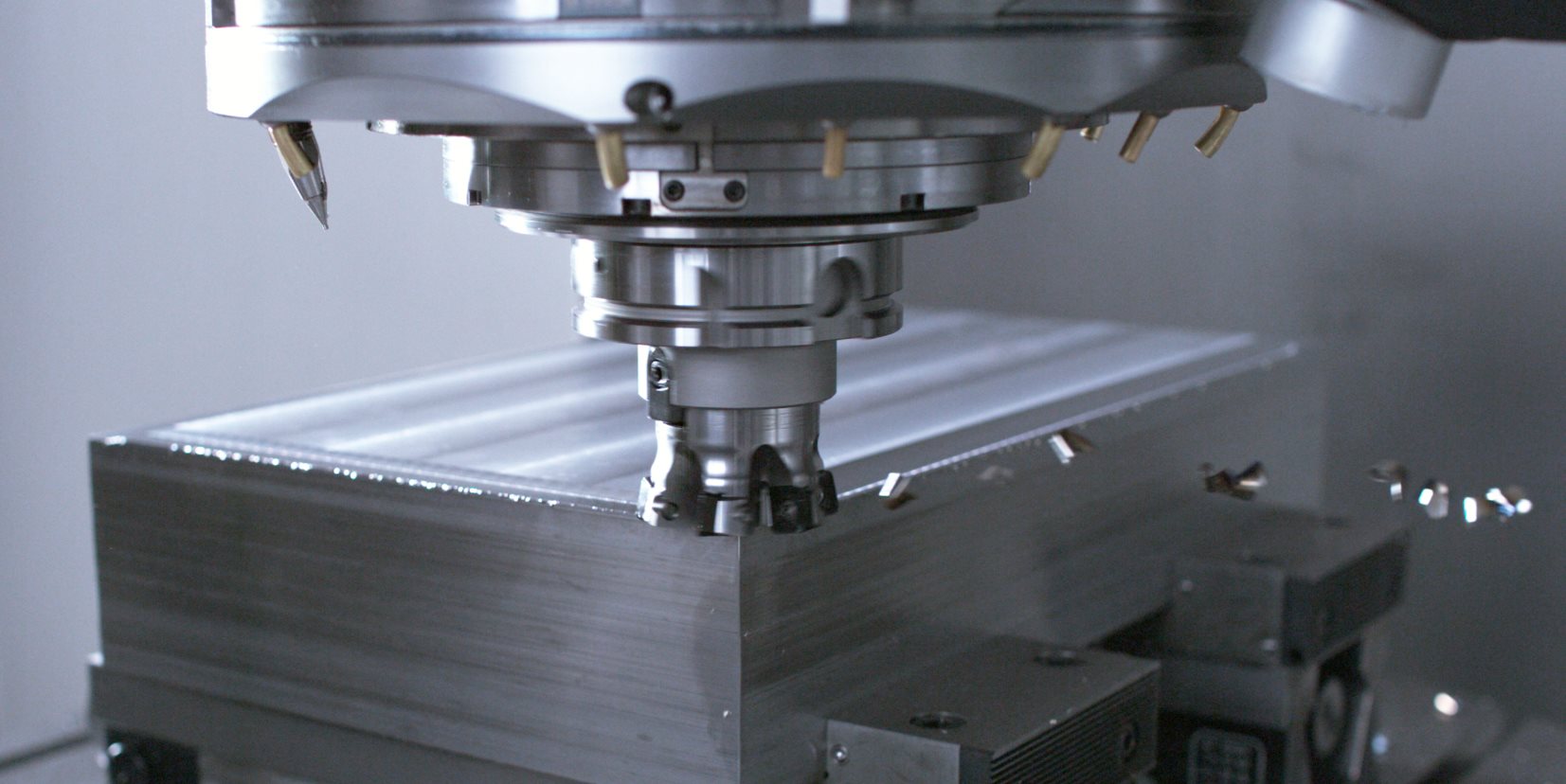

HIGH-FEED PEAK PERFORMANCE IN TOUGH MATERIALS

Whether roughing out a cavity or performing helical interpolation for a large-diameter hole, high-feed milling maximizes material removal in facing, plunging, ramping, helical contouring and more. However, even shallow depths of cut and low cutting forces can’t prevent poor tool life and process reliability in difficult-to-machine materials like stainless steels, superalloys and titanium. A solution that improves process security and increases tool life, the High Feed Square Cut size 14 milling cutter system is ideal for use with tough materials. Four optimized cutting edges available in a full range of proven Seco Tools grades makes it possible to achieve fully secure, fully optimized high-feed milling – and keep your per-edge costs low with outstanding tool life.

Your challenge: Optimal milling requires too many tools, which slows down setup times and increases inventory costs.

The Seco solution: From copy and face milling to ramping and plunging and more, High Feed Square Cut can handle a complete range of high-feed milling applications.

High Feed Cutter insert size 14

Made for predictable cutting behavior and high-performance results, High Feed Square Cut’s four-edge design maximizes tool life for low per-edge costs. Stay in the cut twice as long as the competition with a full range of highly optimized insert grades and lead angles that stay constant for the entire depth of cut, a critical factor for low heat generation and good chip formation. The resulting tools have the reliability you need for secure processes and unattended production – and the wear protection and longevity you need for cost-effective milling.

Your challenge: Built-up or notched edges and broken inserts caused by milling stainless steels, superalloys or titanium increase tooling costs and cause unexpected downtime.

The Seco solution: Boost your tool life in high-feed milling operations with High Feed Square Cut, which offers four cutting edges with geometries optimized for ISO P, M and S materials.

Tough materials require equally tough solutions. High Feed Square Cut milling cutters are more than up to the task thanks to their positive single-sided, straight-edge insert geometries that allow you to push your high-feed milling speeds higher than ever. This solution ensures high feed per tooth whether ramping, pocketing, plunging or performing face or copy milling – and great chip evacuation makes it easy to handle difficult machining operations or milling in deep cavities.

Your challenge: Difficult-to-machine stainless steel, titanium and superalloy milling applications are slowing down your production.

The Seco solution: Improve metal removal rates in ISO P, M and S materials with high-performance High Feed Square Cut size 14 milling cutters.

High Feed coolant

High Feed Square Cut milling cutters make it easier to machine sticky materials, even when it comes to operators’ health – and the world where they live. Designed for easy, ergonomic indexing, the pocket and screw designs simplify positioning. The cutters themselves feature a new environmentally friendly coating, and their outstanding high-feed milling performance reduces the amount of power used in roughing.

Contact Us